HAYMAC DECKING INSTALLATION METHODOLOGY, GUARANTEE & EXCLUSIONS

All guarantees are limited to the original purchaser and will only be upheld on production of your original receipt.

Please always follow the guidance notes available for download from our website for caring for your HAYMAC timber product.

HAYMAC offer a 12-month guarantee against material defect and workmanship on all our products, except where specifically stated below.

Self-installed decks must conform to the HAYMAC Installation & general maintenance requirements for our guarantee to be applicable.

HAYMAC DECKING INSTALLATION METHODOLOGY -

- Deck boards installed such that standing water is not permitted - a minimum 1:100 'fall' installed to the deck. You have the choice to have your deck installed with a less than 1:100 degree of 'fall' or have you deck installed level- see HAYMAC guarantee exclusion DB-11.

- Deck boards installed with 6mm spacing between boards. You have the choice to use smaller gaps -see HAYMAC guarantee exclusion DB-10.

- Deck boards fixed with proprietary decking screws.

- Deck boards fixed to intermediate bearers with 2x fixings per bearer approx. 25% in from the edge of each board.

- Deck board fixings on the ends of deck boards to be installed a min. 25mm from the end of the board with holes pre-drilled to avoid splitting the board.

- Decking bearers at maximum 400mm centres, minimum timber cross section Tanalised UC3 45mmx 95mm @ C24 grade.

- Deck framework installed to offer a minimum 30mm clearance from ground level.

- Weed suppressant membrane installed beneath deck framework.

- Timber framework support posts installed with Postsaver sleeves fitted and concreted into the ground – min. 200mm in depth.

- Deck 'skirt' installed to edges of deck to be installed 30mm above ground - option to have the timber 'skirt' installed to be in contact with the ground (see HAYMAC guarantee exclusion DB-03).

- Deck boards treated after installation, by the customer, with OSMO decking oil/stain which is water repellent with a U.V stabiliser. Annual re-treatment required.

- Regular maintenance undertaken, by the customer, to remove mould/mildew and the build-up of organic materials such as leaves, etc.

DECK BOARDS

DB-01- HAYMAC guarantee against timber rot on our Tanalised softwood timber deck boards allows for the replacement of the deck boards that have suffered timber rot. Supplied only deck board guarantee offers no costs against 3rd party labour to replace or repair the deck, delivery or installation costs or any consequential loss attributed to the defect. HAYMAC supplied and installed deck boards guarantee offers the onsite repair or replacement of the deck boards but does not offer any compensation for any consequential loss attributed to the replacement deck board such as repainting the deck, etc. HAYMAC standard 12-month guarantee only applies if OSMO decking oil treatments have been applied correctly and in line with the manufacturer’s preparation and application instructions - please download our decking care sheet for more information.

DB-02- HAYMAC guarantee on Tanalised softwood timber deck boards is limited to deck boards that have been correctly installed and are installed at a level above ground which ensures contact with the soil or ground has been avoided for the life of the deck board as installed and that general maintenance has been regularly undertaken within the guidelines for maintenance of the product, please download our Tanalised timber decking care sheet for more information. HAYMAC standard 12-month guarantee only applies if OSMO decking oil treatments have been applied correctly and in line with the manufacturer’s preparation and application instructions.

DB-03- HAYMAC offer no guarantee for any Tanalised softwood timber deck board that is in contact with the ground or soil against timber rot or any other structural defect caused by any extraneous interference, i.e., wind damage, malicious damage and vandalism, items stored on the deck boards which allow water to 'sit' on the deck board for prolonged periods or use of the deck board outside of its original designation.

DB-04- The Tanalised timber used in the manufacture of HAYMAC deck boards is not water repellent or U.V sunlight stable. The lifespan of your deck boards will be greatly enhanced with annual applications of a good quality decking treatment. HAYMAC accept no responsibility for any damage caused through water penetration or Ultra Violet sun damage due to inadequate weatherproofing and painting. HAYMAC standard 12-month guarantee only applies if OSMO decking oil treatments have been applied correctly and in line with the manufacturer’s preparation and application instructions - please download our decking care sheet for more information.

DB-05- The timber used in the construction of HAYMAC deck boards is a natural product and is subject to cracks, splits, shrinkage, expansion, cupping, warping, bowing & twisting - as timber is a natural product, this is not considered to be a material defect, and as such, is not covered by our guarantee. In exceptional circumstances, at our discretion, HAYMAC may offer replacement deck boards that have suffered from the above. Should HAYMAC offer replacement deck boards, HAYMAC will not be responsible for any costs against 3rd party labour to replace or repair the decking, delivery or installation costs or any consequential loss. Using OSMO decking oils on your deck will help to limit these issues - please download our decking care sheet for more information.

DB-06- Tanalised softwood timber deck boards will have knots - these knots may become loose and fall from the boards - as timber is a natural product, this is not considered to be a material defect, and as such, is not covered by our guarantee. In exceptional circumstances, at our discretion, HAYMAC may offer the replacement deck boards that have suffered from the above. Should HAYMAC offer replacement deck boards, HAYMAC will not be responsible for any costs against 3rd party labour to replace or repair the decking, delivery or installation costs or any consequential loss.

DB-07- Tanalised softwood timber deck boards during periods of high temperature and when in direct sunlight will dry out to some degree which may cause the deck boards to crack, split, shrink, expand, cup, warp, bow, twist and go grey (as the sunlight bleaches out the green colour treatment). The ends of the deck boards are more prone to splits and visible cupping. This unavoidable natural issue will mean that the joint between the boards can open up allowing a wider than installed visible gap to become apparent - as timber is a natural product this is not considered to be a material defect, and as such, is not covered by our guarantee. Using OSMO decking oils on your deck will help to limit these issues - please download our decking care sheet for more information.

DB-08- Tanalised softwood timber deck boards, during periods of high ambient air moisture content and rain will, to some degree, swell as the deck boards absorb moisture. This unavoidable natural issue will mean that the joint between the boards will appear narrower than the installed visible gap - as timber is a natural product this is not considered to be a material defect, and as such, is not covered by our guarantee. Using OSMO decking oils on your deck will help to limit these issues - please download our decking care sheet for more information.

DB-09- Tanalised softwood timber deck boards require routine maintenance to be undertaken, especially deck boards which are installed in a shaded area or direct sunlight. Deck boards that have a build-up of mildew/mould will decay much quicker, the same will apply to deck boards which have leaves and general organic 'rubbish' allowed to build up and not be removed, this debris will retain moisture and allow fungal growth. Deck boards which are not treated with a water repellent and U.V stable treatment will degrade at a much faster rate and suffer more from cracks, splits, shrinkage, expansion, cupping, warping, bowing & twisting. Deck boards that have not been adequately maintained are not covered by our guarantee. Using OSMO decking oils on your deck will help to limit these issues - please download our decking care sheet for more information.

DB-10- Decking boards installed with a deck board spacing of less than 6mm where instructed by the customer to use a smaller gap will void all guarantees offered for the deck boards and deck framework.

DB-11- Decks installed with a degree of 'fall' less than 1:100 will void all guarantees offered for the deck boards and deck framework.

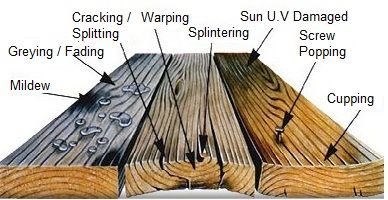

Common Softwood Deck Issues

All Tanalised softwood timber deck boards will suffer from splits, cracks, splintering, shrinkage, expansion, twisting, cupping & warping and timber knots becoming loose and falling out. These issues are unavoidable with Tanalised softwood timber deck boards and as such are outside of our material defect 12-month guarantee. If you are not happy to have these naturally occurring issues present in your Tanalised softwood timber deck boards, please choose an alternative material for your deck boards from an alternative supplier.

Decking Care Sheet

Please click on the image of the broom to download our decking care sheet for information on how to weatherproof and paint your deck and carry out general maintenance to ensure the longevity of your Tanalised softwood timber decking.

DECKING FRAMEWORK

DF-01- HAYMAC offer no guarantee against any timber product that is in contact with the ground or soil against timber rot. Any timber framework support posts which are installed are Tanalised UC3 which offers some degree of protection for the timber post against timber rot. To prolong the life of the post and provide as best as possible protection against timber rot, HAYMAC install a Postsaver sleeve to each timber support post installed. The guarantee for the post saver sleeve is provided by Postsaver - you can download their guarantee below. A concrete framework support post offers the best protection against support post failure. Framework support posts are installed at intervals to provide a solid base framework in line with the cross section of timber framework used for the installation. Support posts will be installed to a minimum depth of 200mm and concreted into the ground using a rapid set post mix.

DF-02- HAYMAC installed decking framework will use, as a minimum, 45mm x 95mm C24 UC3 Tanalised timber installed at a maximum of 400mm centres. HAYMAC standard 12-month guarantee applies.

DF-03- All fixings used for the construction of the deck framework will be exterior grade. HAYMAC standard 12-month guarantee applies.

DF-04- HAYMAC install a weed suppressing membrane beneath the deck framework. HAYMAC do not offer any guarantee on the weed supressing membrane installation or product. We do recommend adding a 30mm layer of 20mm shingle on top of the weed supressing membrane to assist with the weed supressing quality of the installation.

DF-05- Where the deck framework is installed under customer instruction not to have the standard 1:100 degree of 'fall' the framework guarantee will not apply- less than 1:100 degree of 'fall' will void the decking framework guarantee.

DF-06- Where the deck framework cannot be installed due to onsite constraints to have the standard 1:100 degree of 'fall' the framework guarantee will not apply- less than 1:100 degree of 'fall' will void the decking framework guarantee.